National Hire Number

03333 202 555

XMT® 425 Series

Engineered for Precision, Built for Power

Quick Specs

- Rated Output: 10 – 38 V, 5 – 425 A

- Weight: Net 80 lb (36.3 kg), Ship 89.1 lb (40.4 kg)

- Input Power: Requires 3- or 1-Phase Power, 208 – 460 VAC, 50/60 Hz CE

Heavy Industrial Applications

- Construction

- Shipbuilding

- Railroad

- Truck/Trailer Manufacturing

- Fabrication

- Repair Shops

- Rental Fleets

- Power Generation Plants

Processes

- MIG (GMAW)/Pulsed MIG (GMAW-P)*

- Stick (SMAW)

- TIG (GTAW)

- Flux Cored (FCAW)

- Air Carbon Arc Cutting & Gouging (CAC-A)

- *XMT 425 CC/CV requires optional control; not available with XMT 425 VS mode

Unleash Your Welding Potential

The XMT 425 Series is packed with cutting-edge features to tackle the most demanding welding challenges with precision and power.

Genuine Miller Accessories

Optima™ #043 389 A multipurpose, microprocessor-based pulse control for both synergic MIG (wire welding or GMAW) or manual MIG pulsing. Use this control with the XMT 425 CC/CV power source and any Miller wire feeder, including automatic feeders and spool guns. Includes a 25 ft (7.6 m) cord with 14-pin plug. (Not for use with XMT 425 VS model.) Extension Cords for Optima #043 725 25 ft (7.6 m) #043 726 50 ft (15.2 m) #043 727 75 ft (22.9 m) Gas Solenoid Kit #195 286 Easy to install, optional gas solenoid kit for TIG welding applications. Process Selector Control #042 872 Designed for use with dual wire feeders, applications where electrical isolation and/or polarity reversing of weld current is required, and for welding process changes. Includes 115 VAC/ 2 amp receptacle, two 14-pin receptacles and a 10 ft (3 m) 14-pin cord.

WC-24 Weld Control #137 549 Designed for use with Miller CV power sources supplying 24 VAC and 14-pin receptacles. For use with Spoolmatic 30A spool gun.

WC-115A Weld Control #137 546-01-1 Operates on 115 VAC and is designed for power sources without a 14-pin receptacle. For use with Spoolmatic 30A spool gun. Includes 10 ft (3 m) wall-type plug and power cord.

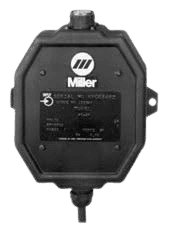

HF-251D-1 High-Frequency Arc Starter and Stabilizer #042 388 Portable 250 amp, 60% duty cycle unit adds high frequency to the welding circuit to help start the arc when using the DC TIG (GTAW) process. Operates on 115 VAC, 50/50 Hz. See Lit. Index No. AY/5.1.

RFCS-14 Foot Control #043 554 Heavy-duty foot current and contactor control. Includes 20 ft (6 m) cord and 14-pin plug.

RHC-14 Hand Control #129 340 Miniature hand control for remote current and contactor control. Dimensions: 4 x 4 x 3-1/4 in (102 x 102 x 82 mm). Includes 20 ft (6 m) cord and 14-pin plug.

RMLS-14 #129 337 14-pin plug. Momentary- and maintained-contact rocker switch for contactor control. Push forward for maintained contact and back for momentary contact. Includes 20 ft (6 m) cord.

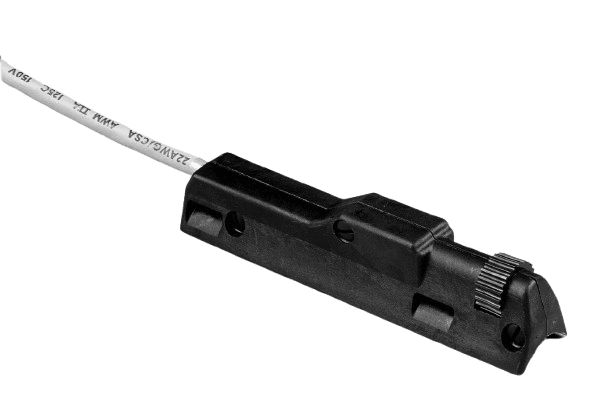

RCC-14 Remote Contactor and Current Control #151 086 14-pin plug. Rotary-motion fingertip control fastens to TIG torch using two Velcro® straps. Includes 28 ft (8.5 m) control cord.

RCCS-14 Remote Contactor and Current Control #043 688 Up-and-down rotary-motion fingertip control. Great for applications that require a finer amperage control. Includes 28 ft (8.5 m) control cord. Extension Cords for Remote Controls and 24 VAC Wire Feeders #122 973 25 ft (7.6 m) #122 974 50 ft (15.2 m) #122 975 75 ft (22.8 m) 14-pin plug to 14-pin socket. Note: Not for use with Optima or 60M Series.

Protective Cover #195 478 Mildew and water resistant, odor-free cover protects your machine’s finish. For 300/350 A inverters: XMT, Maxstar and Dynasty

XMT Cylinder Cart #042 537 Carries two 160 lb (72.6 kg) gas cylinders, or one gas cylinder and one coolant system for TIG (GTAW) welding. Feeder mounts to tray above power source.

Spoolmatic® 30A #130 831 A 1-lb, air-cooled spool gun that extends the weld process range by adding a handy portable system for small wire MIG. Rated 200 A at 100% duty cycle. Includes 30 ft (9.1 m) cable assembly. (WC-24 #137 549 for 14 pin.) Ironmate™ Flux Cored Guns See Lit. Index No. AY/16.0. FC-1260 #195 732 10 ft (3 m) #195 729 15 ft (4.6 m) FC-1260LM #194 912 10 ft (3 m) #194 911 15 ft (4.6 m) FC-1150 #194 864 10 ft (3 m) #194 863 15 ft (4.6 m)

International/Tweco® Adapter #042 465 International/Cam-Lok Adapter #042 466 One-piece adapter with International-style male plug (to power source) on one end and female receptacle (Tweco or Cam-Lok for weld cable connection) on other end. International-Style Connector Kit #042 418 50 mm Accepts #4 or #1/0 AWG cable size. Required if male plugs shipped with power source must be replaced, or if additional plugs are needed. #042 533 70 mm Accepts #1/0 or #2/0 AWG cable size. Required if #1/0 or #2/0 AWG size cable is to be used. Kit includes one International-style male plug which attaches to the work and/or weld cables and plugs into the International-style receptacles on the power source. Extension Kit for International-Style Cable Connectors #042 419 50 mm Accepts #4 or #1/0 AWG size cable. #042 534 70 mm Accepts #1/0 or #2/0 AWG size cable. Used to adapt or extend weld and/or work cables. Kit includes one male International-style plug and one in-line female International-style receptacle.

XMT® 425 Specifications (Subject to change without notice.)

| Input Power | Rated Output at 60% Duty Cycle | Voltage Range in CV Mode | Amperage Range in CC Mode | Max. Open-Circuit Voltage | Amps Input at Rated Load Output, 60 Hz 208V 230V 400V 460V 575V kVA kW | Dimensions | Weight |

|---|---|---|---|---|---|---|---|

| Three-Phase | 350 A at 34 VDC | 10–38 V | 5–425 A | 75 VDC | 40.4 36.1 20.6 17.8 14.1 14.2 13.6 | H: 17 in. (432 mm) W: 12-1/2 in. (318 mm) D: 24 in. (610 mm) | 80 lb (36.3 kg) |

| Single-Phase | 300 A at 32 VDC | 10–38 V | 5–425 A | 75 VDC | 60.8 54.6 29.7 24.5 19.9 11.7 11.2 | H: 17 in. (432 mm) W: 12-1/2 in. (318 mm) D: 24 in. (610 mm) | 80 lb (36.3 kg) |

XMT® 425 Performance Data

Advanced Welding Metrics

Control Panels

- Voltmeter

- Process Selector Switch (Rotary)

- Ammeter

- Voltage/Amperage Adjustment

- Arc Control

- Voltmeter

- Remote Control Receptacle

- Process Selector Switch (Rotary)

- Ammeter

- Voltage/Amperage Adjustment

- Arc Control

Ordering Information

| Category/Item | Stock No. | Description | Qty. | Price |

|---|---|---|---|---|

| Power Source and Options | ||||

| XMT® 425 CC/CV | #907 386 | 208–575 VAC WITH AUTO-LINE™ | ||

| #907 386-01-1 | 230–460 VAC WITH AUTO-LINE™ AND AUXILIARY POWER AND CE | |||

| XMT® 425 VS | #907 387 | 208–575 VAC WITH AUTO-LINE™ | ||

| Accessories | ||||

| Optima™ MIG Pulse Control | #043 389 | FOR CC/CV MODELS ONLY. NOT FOR USE WITH XMT 425 VS | ||

| Optima™ Extension Cords | ||||

| Gas Solenoid Kit | #195 286 | |||

| Process Selector Control | #042 872 | |||

| WC-24 | #137 549 | FOR USE WITH SPOOLMATIC® 30A AND POWER SOURCES WITH 14-PIN | ||

| WC-115A | #137 546-01-1 | FOR USE WITH SPOOLMATIC® 30A AND POWER SOURCES WITHOUT 14-PIN | ||

| HF-251D-1 HF STARTER/STABILIZER | #042 388 | SEE LIT. INDEX NO. AY/5.1 | ||

| RFCS-14 | #043 554 | FOOT CONTROL | ||

| RHC-14 | #129 340 | HAND CONTROL | ||

| RMLS-14 | #129 337 | ROCKER SWITCH | ||

| RCC-14 | #151 086 | FINGERTIP CONTROL | ||

| RCCS-14 | #043 688 | FINGERTIP CONTROL | ||

| EXTENSION CORDS (FOR 24 VAC WIRE FEEDERS AND REMOTE CONTROLS) | SEE PAGE 4. NOT TO BE USED WITH OPTIMA, 60M OR XR-M | |||

| Protective Cover | ||||

| Protective Cover | #195 478 | |||

| Running Gear | ||||

| XMT Cylinder Cart | #042 537 | |||

| Wire Feeders/Guns | ||||

| SuitCase® 8VS/X-TREME™ 12VS | #194 890 / #195 500 | SEE LIT. INDEX NO. M/6.4 AND M/6.41 | ||

| SuitCase® 8RC / 12RC | #194 938 / #194 940 | SEE LIT. INDEX NO. M/6.5 | ||

| XR™-Control | #181 538 | SEE LIT. INDEX NO. M/1.7 | ||

| 70 SERIES | #195 057 | S-74S. SEE LIT. INDEX NO. M/3.0 | ||

| #195 058 | S-74D. SEE LIT. INDEX NO. M/3.0 | |||

| #195 059 | S-74DX. SEE LIT. INDEX NO. M/3.0 | |||

| Spoolmatic® 30A Spool Gun | #130 831 | INCLUDES 30 FT (9.1 M) CABLE ASSEMBLY | ||

| Ironmate™ Flux Cored Guns | SEE LIT. INDEX NO. AY/16.0 | |||

| Water Coolant Systems | ||||

| Water Coolant Systems | SEE PAGE 6. SEE LIT. INDEX NO. AY/7.2 | |||

| International-Style Connectors | ||||

| International-Style Connectors | SEE PAGE 6 | |||

| TOTAL QUOTED PRICE: | ||||